FIRE FIGHTING EQUIPMENTS

Fire hose reel

MIPL 1100 Fully Automated Vacuum Impregnation Machine

SALIENT FEATURES MIPL 1100

Flexible basket design allows 4 small trays or can be modified to 2 big trays as per the requirement

PP fixturing ensures that there are no dent damages to the machined castings.

Safety fencing with safety doors interlocked with the gantry PLC for operator safety.

Maintenance platform with CAT Ladder & safety door interlocked with the gantry PLC for Operator safety.

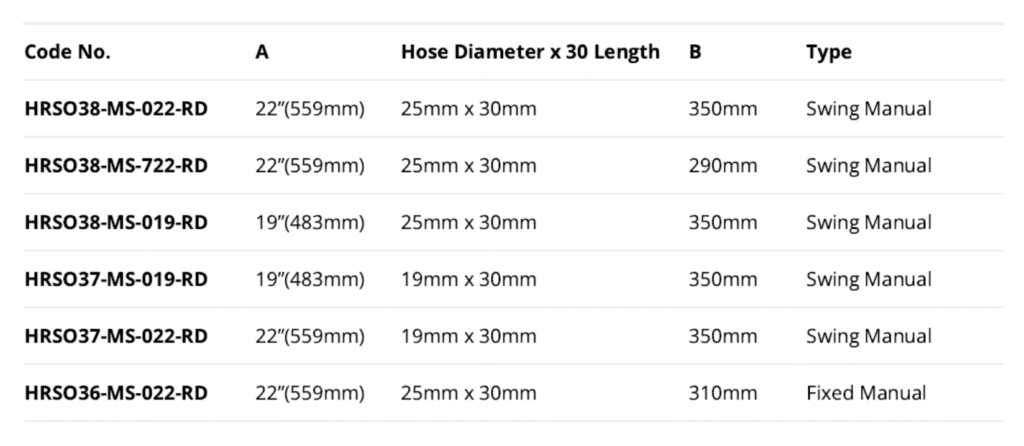

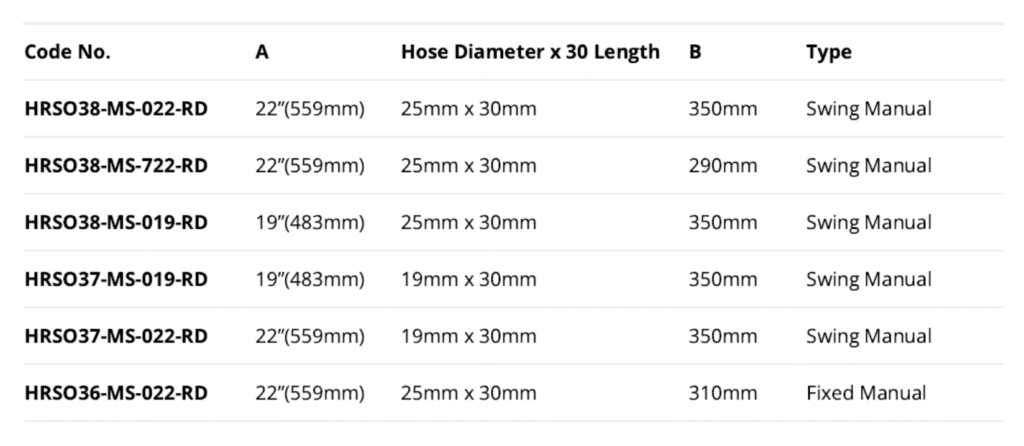

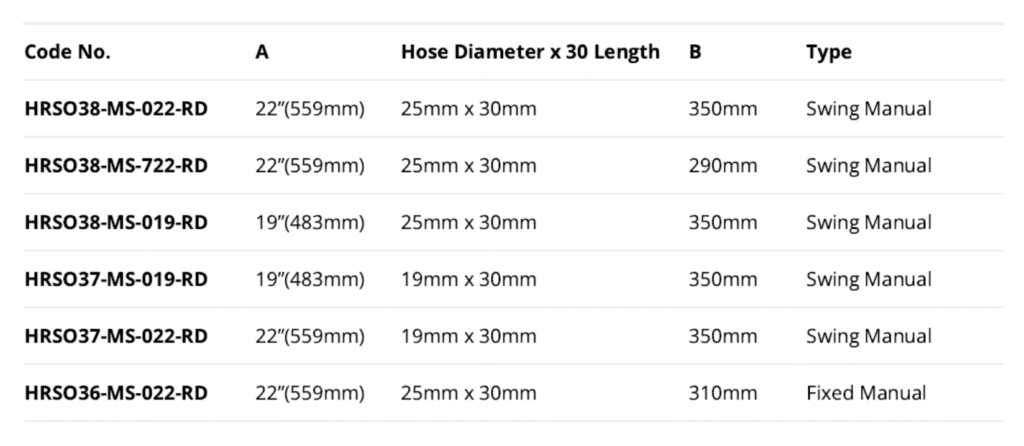

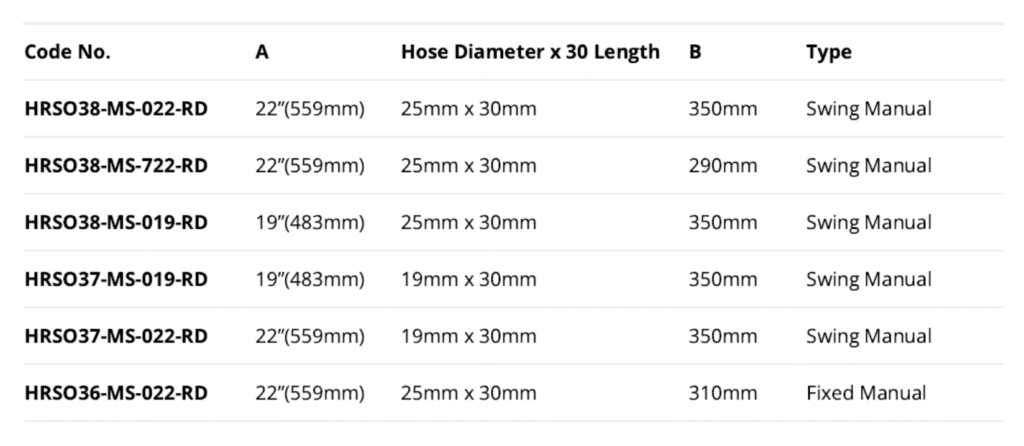

SRI fire hose reels are tested and approved to European Standard EN671 by British Standers Institution andto Australian Standards AS1221 by QAS Australian. These approvals require the certification authority tocarry out regular inspection of our hose reels manufacturing facility, testing of hose reels and auditing ofquality system. With rigorous inspection and testing of our fire hose reels during production the perfor-mance and reliability is at the highest standard. SRI manufactures a wide selection of fire hose reel, “3/4”and 1”, swing and fixed type, manual and automatic. Swing type hose reel has double 1800 rotating hinge,which allows hose reel to be mounted in a recessed wall and fixed type hose reel is complete with hoseguide which allows the hose withdrawal in all direction.

MIPL 1500 Fully Automated Vacuum Impregnation Machine

SALIENT FEATURES MIPL 1500

Equipped with a Stainless Steel basket

with PP fixturing, patented by Teknoseal Group

Fitted with 8 removable trays, depending

on the size of the castings being impregnated,

Flexible design for either 2 large trays, 4

medium trays or 8 small trays depending on customer needs.

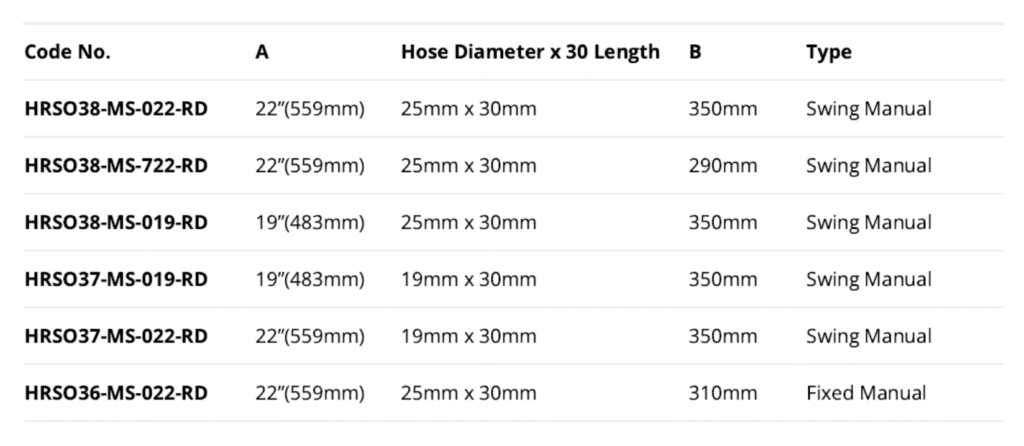

Designed to handle high volumes effortlessly

SRI fire hose reels are tested and approved to European Standard EN671 by British Standers Institution andto Australian Standards AS1221 by QAS Australian. These approvals require the certification authority tocarry out regular inspection of our hose reels manufacturing facility, testing of hose reels and auditing ofquality system. With rigorous inspection and testing of our fire hose reels during production the perfor-mance and reliability is at the highest standard. SRI manufactures a wide selection of fire hose reel, “3/4”and 1”, swing and fixed type, manual and automatic. Swing type hose reel has double 1800 rotating hinge,which allows hose reel to be mounted in a recessed wall and fixed type hose reel is complete with hoseguide which allows the hose withdrawal in all direction.

MIPL 825 Semi Automated Pick and Place Vacuum Impregnation Machine

SALIENT FEATURES OF MIPL 825

SS baskets with removable type tray having pp fixturing.

Designed with single tray per basket

PP fixturing to prevent dent damages to castings.

Rotary Wash-1 chamber and Rotary Wash-2 chambers are connected to the SWRS system for sealant recovery from wash water.

Fully automatic pick and place robotic gantry system

Safety fencing, safety doors interlocked with the gantry plc for operator Safety.

Maintenance platform with CAT ladder & safety door interlocked with the Gantry plc for operator safety

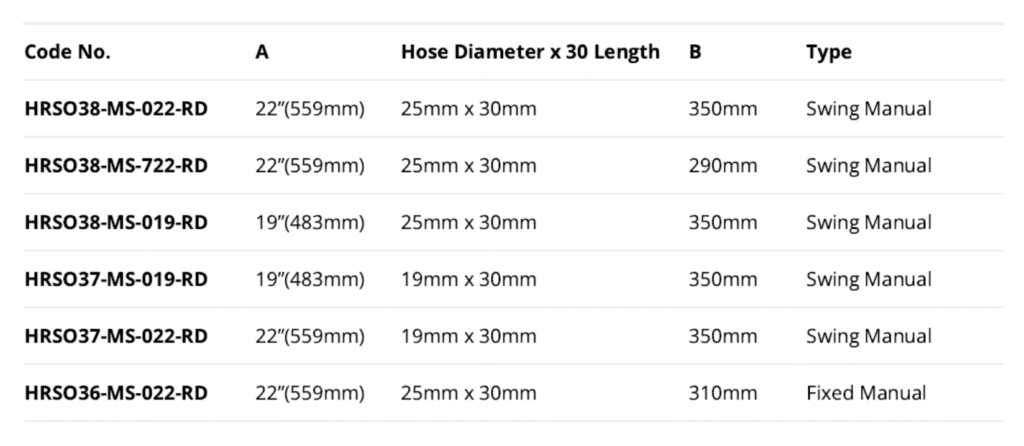

SRI fire hose reels are tested and approved to European Standard EN671 by British Standers Institution andto Australian Standards AS1221 by QAS Australian. These approvals require the certification authority tocarry out regular inspection of our hose reels manufacturing facility, testing of hose reels and auditing ofquality system. With rigorous inspection and testing of our fire hose reels during production the perfor-mance and reliability is at the highest standard. SRI manufactures a wide selection of fire hose reel, “3/4”and 1”, swing and fixed type, manual and automatic. Swing type hose reel has double 1800 rotating hinge,which allows hose reel to be mounted in a recessed wall and fixed type hose reel is complete with hoseguide which allows the hose withdrawal in all direction.

CASTING LUBRICANTS

MORESCO DIE CASTING LUBRICANTS have long been recog-nized as industry leaders. World class technology, coupledwith our commitment to customer satisfaction of die casterswho seek to improve their quality, productivity and profitabil-ity. Since then we have continually developed innovativesolutions.

MORESCO (Thailand) Co. Ltd. with its State of the Art R&D fa-cilities and capabilities, enables it to support the needs of thecustomers with a new range of die lubricants that reduces cy-cle times and increases productivity, excellent die release andgood lubrication for pins and ejectors. If customer parts re-quire painting, MORESCO has the answers